The great thing about building your own airplane is the ability to customize. As this plane is considered by the FAA to be “experimental”, we have the freedom to do whatever we want.

1. Air Conditioning

On average, for every 1,000′ an aircraft climbs, the temperature drops 1.98C. This is known as a standard adiabatic lapse rate.

We live in Florida where in summer it can be 36C (97F) on the ground but still 28C (82F) up at 4,000′. Still too hot to be comfortable. You’d need to be up at 7,000′ just to get 22C (72F)! We want comfort from the moment the engine is started! Princesses!

We flew in a Cessna 310 recently at about 2500′ in 95F and decided, whatever the cost to get air conditioning, we’ll pay it!

There are 3 companies that make air conditioning for the RV-10 but I think we might go with Airflow Systems.

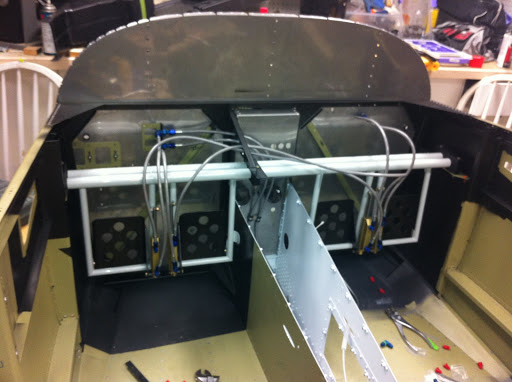

The compressor is driven off the front of the engine and the evaporator sits in the tail cone just aft of the baggage compartment. The whole thing weighs less than 30 lbs.

2. Custom Rudder Pedals

I’ve never been a huge fan of Van’s rudder pedals. The way the brake lines are routed in front of the rudders doesn’t look great. Although servicing would be a snap.

Control Approach makes a very nice product. We will most likely add this during fuselage construction. The brake lines run behind the rudder pedals and look more like a production aircraft.

3. Custom Wingtips

Van’s wing tips are a little too pedestrian for a nice plane like the RV-10. Additionally, a huge hole must be cut in the leading edge to accommodate a landing light which we’d like to avoid.

With a product from Aveo Engineering called ZipTips you get Landing Lights, Taxi Lights, Wigwags, Strobes, and Nav lights all in the same location. This makes wiring easier and the lights are amazingly bright.

4. 9:1 Compression Ratio

Nominal horse power of an IO-540 is roughly 260. This is fine, but increasing the compression ratio just a bit can get it closer to 275.

5. Electronic Ignition

Things have really changed in the last 30 years in the world of experimental aircraft. Whereas most general aviation engines have been using magnetos invented in the 1800s, todays modern electronic ignition systems such as P-MAG, EFII, or SDS have dramatically increased aircraft efficiency, power, and run noticeably smoother.

The latter 2 systems allow the pilot to vary the timing of the engine as well as the fuel delivered to each individual cylinder. EFII and SDS have also removed the need for a mixture control knob. The fuel is metered to the engine just like a car based on throttle position, engine RPM, air temperature, engine temperature and so on.

These systems can be installed in pairs to allow for full redundancy just like dual magneto engines of the past.

6. Oxygen

The ‘happy medium’ between high power, high drag at lower altitudes vs. low power, low drag at higher altitudes happens between 12,000 to 15,000 with this engine. As we are wanting go long distances with this plane and cruise at these higher altitudes, we will need to be using oxygen.

Newer oxygen systems include a built-in pulse oximeter for each occupant allowing just the right amount of oxygen to flow given their individual physiological state.

Mountain High makes a beautiful system that is built into the aircraft during fuselage construction.

7. Beringer wheels, tires, and brakes

The tires on an RV-10 contain inner tubes just like a bicycle. The inner tube must be inserted carefully to avoid any folds. This can be difficult and if done wrong can cause a tube to blow out prematurely.

Beringer tires are tubeless just like a car. To change a tire, simply remove the bolts that hold the 2 halves of the wheel together, replace the tire, bolt the 2 halves back together again and you’re done! Oh, and don’t forget to add the air!

Beringer has been making brakes for racing for many years. They provide better braking even when they are hot and the look really cool!